Ngesikhathi sokusetshenziswa kwesikhathi eside komshini we-pellet we-biomass, okukhiphayo kuzokwehla kancane kancane, futhi izidingo zokukhiqiza ngeke zihlangabezane.

Kunezizathu eziningi zokuncipha kokuphuma komshini we-pellet. Kungenzeka ukuthi ukusetshenziswa okungalungile komsebenzisi komshini we-pellet kubangele ukulimala engxenyeni yomshini we-pellet, noma awuzange ufakwe ngendlela efanele ngesikhathi sokufakwa, futhi awuzange uhlangabezane nezidingo ezijwayelekile. , Ngamafuphi, ukwehla komkhiqizo kuyikhanda elibuhlungu elithinta ukuthuthukiswa kwamabhizinisi.

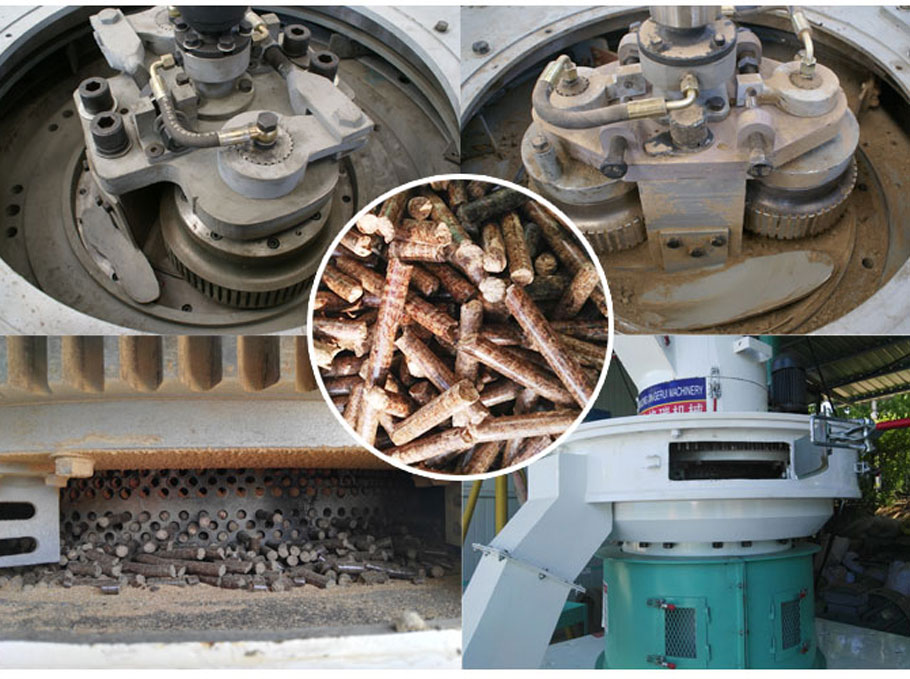

Namuhla, umhleli we-Kingoro uzogxila ekuchazeni ukuthi umthelela wesikrini ubaluleke kangakanani ekukhishweni komshini we-pellet we-biomass.

1. Ubude besikrini bunquma ukusebenza kahle kokuhlola, futhi ububanzi besikrini bunquma ukuphuma komshini we-pellet we-biomass. Ukuze sikhulise okukhiphayo, singalungisa indlela yokuphakela, ukuze okokusebenza kumele kudliwe ngobubanzi besikrini esigcwele, ukuze kungakhushulwa kuphela Okukhiphayo, futhi isikrini sisetshenziswe ngokugcwele, kugwenywe ukwenzeka kwezinsiza ezingasebenzi;

2. Thuthukisa izinga lokuvula isikrini somshini we-pellet: uma sikhulu izinga lokuvula, izinto eziningi zizodlula esikrinini ngehora, okubuye kube nenzuzo kakhulu ekuthuthukiseni umphumela wokuhlola nokwandisa ukukhishwa kwemishini ye-biomass pellet machine. indlela;

3. Ukusetshenziswa kokuhlolwa okumanzi akukwazi nje ukwandisa okukhiphayo, kodwa futhi kunciphise ukukhishwa kothuli okukhiqizwa ngesikhathi sokuhlola futhi kungcolise umkhathi, okubuye kube nenzuzo kakhulu ekuvikelweni kwemvelo. Ukuze unciphise i-batter porosity yesikrini, cabanga ukwengeza amabhola abhampayo ukuze uhlanze isikrini futhi usebenzise idivayisi ye-ultrasonic. Uma i-mesh yesikrini ivinjiwe, inani lezinto ezidlula esikrinini lizoncishiswa, okuzonciphisa okukhiphayo futhi kugcine isikrini. Imigodi engavinjwanga nayo ingenye yezindlela ezinhle zokwandisa isivuno.

4. Ukwandisa amandla emoto: amandla enjini angumthombo wamandla oyinhloko womsebenzi wokuhlola kanye namandla amakhulu okuqedela umsebenzi wokuhlola. Ukwandisa kahle amandla emoto kungakhuphula ukuphuma kwemishini yomshini we-pellet;

5. I-angle yokuthambekela ye-pellet mill ingalungiswa. I-engeli yokuthambekela efanelekile iyazuzisa ukunciphisa ukushuba kwezinto futhi ubone ukuhlungwa kwezingqimba zezinto ezincane. Sonke siyazi ukuthi uma inani lokuphakela likhulu kakhulu, izinto ezibonakalayo zizoqongelela ngokungathí sina, okungeke kuholele ekusebenzeni kahle kokuhlolwa Akulungile kakhulu uma yehliswa, futhi ingalimaza isikrini;

6. Ukunciphisa i-batter porosity yesikrini, cabanga ukwengeza amabhola abhampayo ukuze uhlanze isikrini futhi usebenzise idivayisi ye-ultrasonic. Uma i-mesh yesikrini ivinjiwe, inani lezinto ezidlula esikrinini lizoncishiswa, okuzonciphisa okukhiphayo. Ukugcina ukuvuleka kwesikrini kungavimbekile futhi kungenye yezindlela ezingcono kakhulu zokwandisa ukukhiqizwa.

Isikhathi sokuthumela: May-19-2022